Smart Operations Decision Support Technology

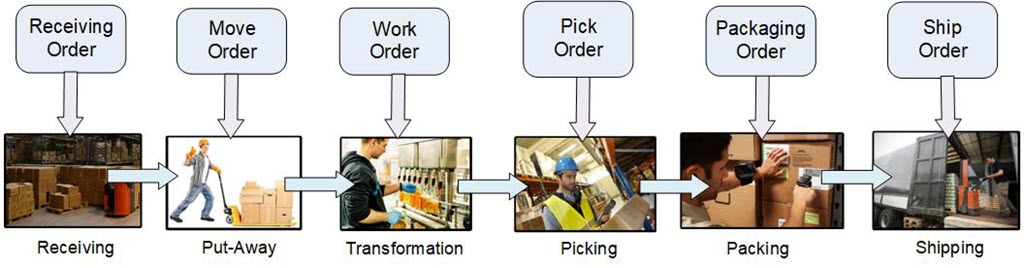

Smart Operations Management (SOM) systems are comprised of the stack of

capabilities shown above, which integrate factory floor data collection with

front-office operations management decision support. In these systems,

operational status information flows from the factory floor to the front office,

where decision support algorithms algorithms convert the operational status

information into orders for manufacturing and warehouse workers.

These SOM systems typically automatically exchange data with a variety of other systems,

both to gather data they need and to export data to the systems that need

the information collected by the SOM system.

SOM systems are a fusion of a number of technologies:

- Intelligent real-time operational data collection – saving the time wasted by production workers and material handlers manually collecting

operational status data using paper forms, Excel spreadsheets, and manual data entry into multiple computers,

by replacing these with automated data collection using technologies such as barcode and RFID tracking, as well as direct integration with process control

equipment, weighing scales, barcode label printers, and test stands.

- Real-time point-of-action data collection, enabling intelligent guidance of data entry by production workers and material handlers,

as well as the immediate detection and correction of data entry or operational mistakes.

- Real-time data fusion from multiple geographically distributed sources in manufacturing plants, and warehouses,

as well as at construction and other field sites, to provide operations managers and their staff with a real-time

view of their operations so that they, and their staff can make sure that customer orders get out on time without

the need for walking round the shop-floor expediting orders.

- Use of ruggedized industrial internet of things (IOT) computers in each plant or warehouse for data collection and local operations process management flow,

so that operations can continue even if the Internet is down or becomes very slow or unreliable.

- Use of “battlefield hardened” encrypted store-and-forward communications technology between IOT computers at different sites and centralized servers

in the Cloud to ensure that data is not lost even when communications is intermittent due to Internet or other data link failures

or data collection is being performed at construction sites or other locations where there is no Internet connection.

- Use of real-time intelligent agents to perform “intelligent grunt work” operations-management tasks such as:

- Automating the planning process of turning a flow of customer orders, from multiple sources, into manufacturing and shipping orders and then

automatically routing these orders through work centers in different manufacturing plants and warehouses.

This not only saves a lot of planning time but improves sales competitiveness by enabling shorter delivery time.

- Automating real-time scheduling of jobs through work-centers to make sure customer orders get out on time.

This avoids the need for managers and their staff to attend endless production coordination and planning meetings

or for production workers to waste time waiting for their supervisor to decide what to work on next.

- Automatically performing operational status data entry into ERP, accounting and other systems thus

avoiding time wasted doing duplicate data entry. Also makes sure that the data in these systems

is always up to date and not a day or two late, which often happens with manual data entry.

- Automatically monitoring data in multiple systems for operational problems and sending alert Emails to managers and their staff as

soon as problems occur. This avoids the need for production managers and their staff to wade through paper forms,

Excel spread-sheets, or reading reports from their ERP system about what went wrong yesterday.

- Automatically compiling and sending out periodic reports tailored to the specific needs of each recipient, such as products waiting for QC,

the cost of each job by task versus the estimated cost, and a labor and machine-time breakdown about how long each job took.

Today, smart operations management solutions are primarily used today to extend

the capabilities of ERP and accounting systems so that they can perform

real-time operations tracking and process flow management but, in future,

may increasingly displace the operations planning and management functions

of ERP systems.

SOM systems use a variety of AI technologies to perform their tasks.